Automatic motion detector

Automatic validation during your item pick and drop actions.

Automatic gesture detection

• Laser barrier that detects the placement or picking of a product.

• Detects picking or sorting errors.

Validations are done automatically when the operator passes in front of our motion detector. The system is compatible with all our Go-to-Light visual guidance solutions.

- Work hands-free

- Even faster

- Fewer errors

- Display in red when an error is detected

Advantages of the motion detector

Error reduction

The system alerts the operator in case of errors and does not validate the operation.

Increased efficiency

Smoother movements, no time wasted on scanning.

Work comfort

The detector allows the operator to minimize their movements and avoid unnecessary tasks.

Improved traceability

You can better track and document the movements of items.

Laser barrier type motion detector

How it works

Motion detector to be installed on a cabinet, shelf, or rack, enabling the detection of different locations:

- 2D motion detector

- Highly accurate

- Range up to 15 m

Thanks to this system, the error rate is close to 0.

Use cases for this detection:

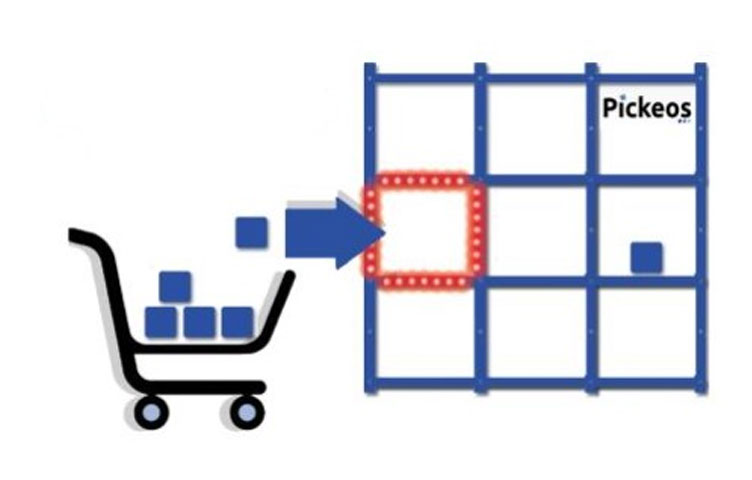

![]() Picking Zone:

Picking Zone:

The order picker works hands-free without needing to scan products. Zone information can be displayed on a tablet or terminal mounted on a cart. As soon as the picker moves their hand in front of the correct product, the system validates the pick and moves to the next product.

![]() Sorting Wall:

Sorting Wall:

The operator scans the product to be sorted. The zone where the item should be placed is displayed using the Go-to-Light system. The operator places the item in the designated area indicated by the LEDs. If it’s the correct zone, the light turns off. If it’s not the correct zone, an alert notifies the operator (visual and audible alert optional).

![]() Kitting:

Kitting:

At your assembly stations, for kit preparation, the correct part pick is validated by the motion detector. If the operator makes a mistake, they are alerted, and the operation is not validated.

![]() Restocking:

Restocking:

This lidar detection system can be integrated into inventory and restocking processes. It enables a more proactive and efficient approach to managing parts and materials. You can monitor stock levels in real-time and automatically trigger restocking whenever parts are picked, preventing both stock shortages and excess inventory.

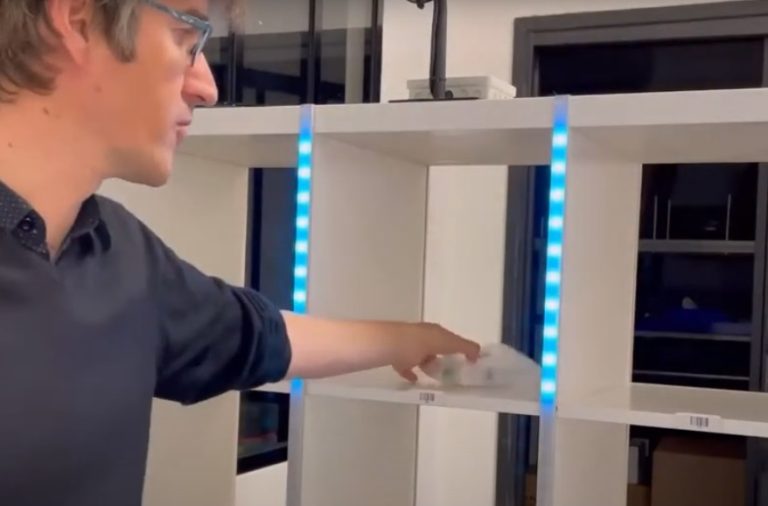

Discover our solution in video

Presentation of a possible use case in a sorting wall:

Busting hive after a global picking preparation.

Use on sorting furniture

Discover our ventilation furniture optimized for ultra-fast sorting without errors.

Combine the Go-to-Light visual guidance with LED strips that indicate the section where to place your item in the sorting area.

Minimize errors and increase speed!

Discover all our solutions for the industry

Modern and versatile technologies for industrial use

Kitting

Prepare your kits and parts more easily

Quality and Safety

Warning lights, equipment availability, maintenance support.

Component Management

Minimize stockouts at assembly stations.

Production Lines

Restocking at workstations and assembly lines.